BETTER TOUCH BETTER BUSINESS

Contact Sales at FURUI.

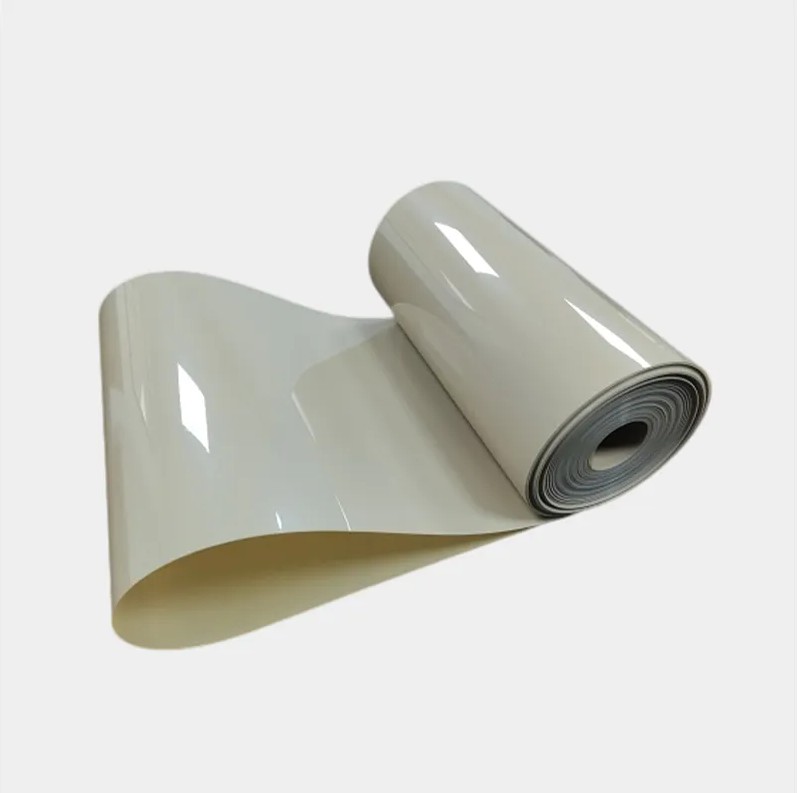

PEEK Film (Polyether Ether Ketone) has become an essential material in modern electronics due to its outstanding properties. Known for its high thermal stability, electrical insulation, and mechanical strength, PEEK Film is increasingly used in a variety of electronic applications. For businesses or engineers seeking advanced materials to improve their electronic components, understanding the advantages of PEEK Film is crucial. This article will explore how PEEK Film enhances electronics performance and offer guidance on what to consider when purchasing it from a PEEK Film supplier or PEEK Film manufacturer.

One of the most significant advantages of PEEK Film is its ability to withstand extreme temperatures, often reaching up to 260°C. This high thermal stability makes it ideal for electronic components that operate in harsh environments, such as industrial machinery, automotive systems, or high-performance computing devices. Unlike other materials that degrade or lose their structural integrity at elevated temperatures, PEEK Film retains its mechanical properties, ensuring long-term performance.

PEEK Film also provides excellent dielectric properties, making it an outstanding electrical insulator. This is crucial in electronic applications where preventing short circuits and electrical failure is paramount. Whether used in printed circuit boards (PCBs) or cable insulation, PEEK Film ensures that the electrical performance remains stable and reliable. For companies needing high-quality insulation materials, working with a reputable PEEK Film manufacturer guarantees that the film will meet the demanding requirements of electronic manufacturing.

In addition to thermal and electrical properties, PEEK Film exhibits impressive mechanical strength. This allows it to endure the physical stresses associated with modern electronics, such as bending, stretching, or exposure to mechanical forces. PEEK Film maintains its structural integrity even under pressure, making it suitable for precision components in advanced electronics, where durability is essential for performance.

PEEK Film is known for its remarkable resistance to chemicals, including acids, solvents, and oils. This property is particularly beneficial in electronic components exposed to aggressive environments, such as those used in automotive electronics or industrial machinery. PEEK Film acts as a protective layer, ensuring the electronics remain unaffected by corrosive substances, thereby extending the lifespan of the device. For those in need of chemical-resistant materials, selecting a reliable PEEK Film supplier is essential to ensure the film meets industry standards and offers long-term protection.

Despite its strength, PEEK Film is lightweight and flexible, which makes it ideal for modern electronic designs where space and weight constraints are a concern. This combination of lightweight and flexibility allows engineers to incorporate PEEK Film into complex systems without adding unnecessary bulk. Its flexibility also makes it compatible with the rising demand for flexible electronics, such as wearables, where traditional materials might fail to meet the required performance.

PEEK Film is widely used in printed circuit boards due to its superior thermal and electrical properties. It serves as an insulation layer in PCBs, where maintaining electrical isolation between different parts is critical for performance. In high-temperature environments or applications where reliability is paramount, PEEK Film ensures the integrity of the circuit board remains intact, preventing failures and reducing maintenance costs.

PEEK Film enhances the durability and safety of electrical connectors and cable insulation. By using PEEK Film, manufacturers can create components that resist heat, chemicals, and mechanical stress, ensuring a longer lifespan and greater reliability. Choosing a high-quality PEEK Film manufacturer is crucial to guarantee that the film will meet the rigorous demands of these applications, especially in sectors like aerospace or automotive, where reliability is non-negotiable.

The ability of PEEK Film to withstand high temperatures and offer electrical insulation makes it ideal for use in semiconductors and sensors. These components are often sensitive to environmental conditions, and PEEK Film provides the necessary protection to ensure they function optimally. As the electronics industry continues to evolve, incorporating PEEK Film into semiconductor designs helps improve performance and miniaturization without compromising durability.

With the growing trend toward flexible and wearable electronics, PEEK Film has emerged as a key material due to its flexibility and strength. Whether used in bendable displays or wearable devices, PEEK Film maintains its properties under stress and offers long-term performance. Electronics manufacturers working with flexible devices can benefit significantly by sourcing PEEK Film from trusted suppliers who understand the specific needs of the industry.

While polyimide films like Kapton are popular in electronics for their heat resistance, PEEK Film offers superior mechanical properties, making it a better choice for applications where both flexibility and strength are required. PEEK Film's ability to withstand higher mechanical stress makes it more suitable for high-demand applications.

Compared to PTFE (Teflon), PEEK Film provides better overall durability, particularly in applications requiring mechanical stability and chemical resistance. Although PTFE is widely used for its electrical insulation properties, PEEK Film offers a more robust solution in environments exposed to both mechanical and chemical stress.

By understanding these differences, buyers can make an informed decision when selecting a PEEK Film supplier to ensure they are getting the right material for their specific application.

When purchasing PEEK Film, it is essential to consider the specific thickness and size requirements of your application. Thicker films provide greater mechanical protection, while thinner films offer more flexibility. Ensure that the PEEK Film you select from the PEEK Film manufacturer matches the dimensions needed for your project.

PEEK Film must meet certain quality and certification standards, especially in industries like aerospace and medical electronics. Buyers should verify that their PEEK Film supplier adheres to relevant international standards, such as ISO certifications, to ensure the product's reliability and safety.

Choosing the right PEEK Film supplier is critical to ensure the quality and performance of the material. Look for suppliers who have experience in the electronics industry and can provide customized solutions to meet your specific needs.

PEEK Film contributes to sustainability by increasing the lifespan of electronic components. Its durability and resistance to environmental factors reduce the need for frequent replacements, which in turn lowers electronic waste and overall production costs.

The thermal and electrical insulation properties of PEEK Film also contribute to energy efficiency in electronic devices. By preventing overheating and minimizing energy loss, PEEK Film helps electronics operate more efficiently, which is a growing concern in today's eco-conscious market.

While PEEK Film itself is a long-lasting material, it is also recyclable, making it a more environmentally friendly choice compared to other plastics. Electronics manufacturers focused on sustainability can benefit from incorporating PEEK Film into their designs to reduce their environmental impact.

In conclusion, PEEK Film offers numerous advantages for electronics components, from high thermal stability and electrical insulation to mechanical strength and chemical resistance. Its applications span a wide range of electronic devices, from PCBs and connectors to flexible electronics and semiconductors. When selecting PEEK Film, buyers should consider thickness, quality standards, and the reliability of the PEEK Film supplier. For those looking to improve performance and durability while also contributing to sustainability, PEEK Film is an excellent choice.

Copyright © 2025 Guangzhou Furui New Material Technology Co., Ltd.| All Rights Reserved