BETTER TOUCH BETTER BUSINESS

Contact Sales at FURUI.

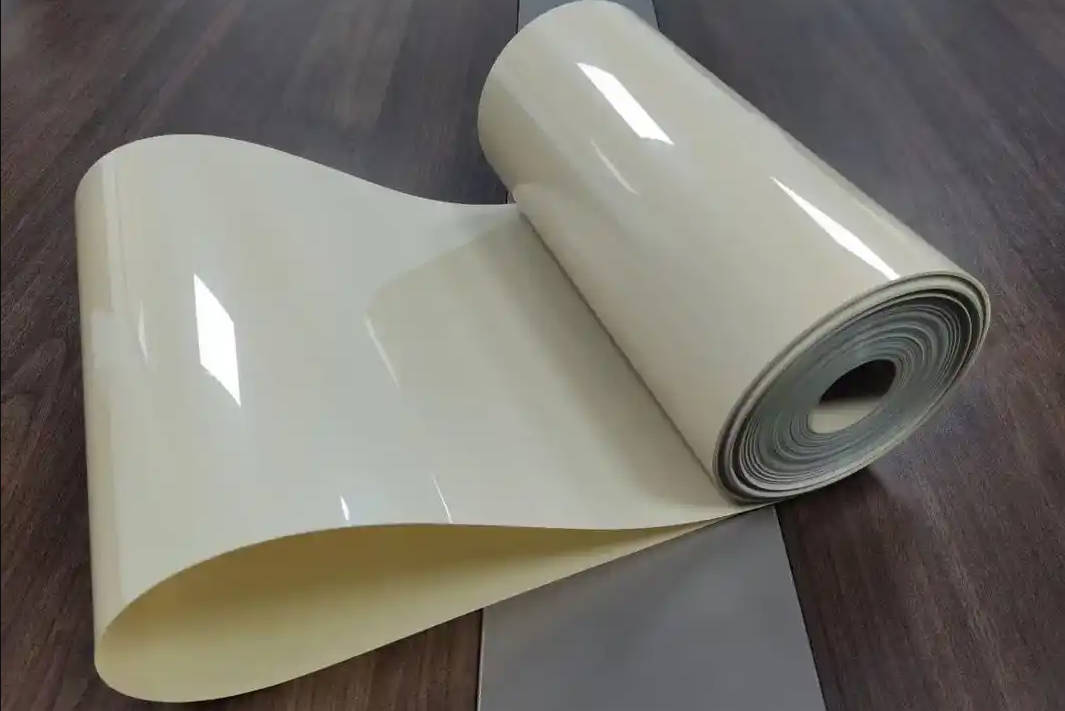

Polyetheretherketone (PEEK) is a high-performance thermoplastic known for its exceptional thermal stability, chemical resistance, and mechanical strength. These properties make PEEK films highly sought after in various industries, including aerospace, electronics, and medical devices. However, the effectiveness of PEEK FILM Coating services largely depends on the adhesion of coatings applied to these films. Surface treatments play a crucial role in enhancing the adhesion of coatings on PEEK films. This article aims to inform potential buyers about how different surface treatments can impact the performance and durability of PEEK film coatings, helping them make informed decisions when seeking PEEK FILM manufacturers or suppliers. PEEK exhibits remarkable properties that make it suitable for demanding applications. It can withstand high temperatures (up to 260°C) and is resistant to a wide range of chemicals, including acids and solvents. Additionally, PEEK has excellent mechanical strength, making it ideal for structural components in critical applications. Coatings applied to PEEK films serve multiple purposes, such as enhancing wear resistance, improving surface properties, and providing additional functionalities like electrical insulation or EMI/RFI shielding. The effectiveness of these coatings is significantly influenced by the adhesion between the coating and the PEEK substrate. Surface treatments refer to various processes applied to modify the surface characteristics of materials to improve their performance. In the context of PEEK films, these treatments aim to enhance adhesion with coatings, thereby increasing the overall durability and functionality of the final product. Several surface treatment methods are commonly used for PEEK films: Mechanical Treatments: Techniques such as sanding or blasting can create a roughened surface that increases the contact area between the coating and the substrate. Chemical Treatments: Methods like plasma treatment or chemical etching alter the surface chemistry of PEEK films, enhancing their surface energy and promoting better bonding with coatings. Thermal Treatments: Processes such as annealing can modify the molecular structure of PEEK films, potentially improving adhesion properties by aligning polymer chains. Adhesion between a coating and a substrate involves both physical and chemical interactions. Understanding these mechanisms is essential for optimizing coating performance on PEEK films. Mechanical treatments can significantly enhance adhesion by increasing the surface roughness of PEEK films. A roughened surface provides more mechanical interlocking points for the coating, leading to improved adhesion strength. This is particularly important for applications where durability and resistance to wear are critical. Chemical treatments modify the surface energy of PEEK films by introducing functional groups that promote bonding with coatings. For instance, plasma treatment can increase hydroxyl or carboxyl groups on the surface, which can chemically bond with certain types of coatings. This enhancement in surface chemistry is vital for achieving strong adhesion in demanding environments. Thermal treatments can affect the crystallinity and molecular orientation of PEEK films. By carefully controlling temperature and time during annealing processes, manufacturers can optimize the molecular structure for improved adhesion properties. This approach is particularly beneficial when working with high-performance coatings that require robust bonding to withstand extreme conditions. Please let me know when you would like me to continue! Numerous industries have successfully utilized PEEK FILM Coating services, particularly in aerospace and medical sectors. For instance, a study demonstrated that oxygen plasma treatment significantly improved the adhesion of TiO2 coatings on PEEK films, enhancing their performance in biomedical applications. This method increased the number of oxygen-containing functional groups on the surface, which facilitated better bonding with the coating material 1. Such advancements illustrate the critical role of surface treatments in achieving high-performance coatings. Comparative studies have shown that treated PEEK films outperform untreated ones in adhesion tests. For example, untreated PEEK films typically exhibit low bond strength due to their non-polar surface properties. However, after undergoing surface treatments like plasma or corona treatment, the surface energy can increase significantly, leading to improved adhesion characteristics. In practical applications, this translates to enhanced durability and functionality of coated components, which is vital for industries that rely on high-performance materials 5. When selecting a surface treatment for PEEK films, several factors should be taken into account: Type of Coating: Different coatings may require specific surface treatments to achieve optimal adhesion. For instance, metallic coatings may necessitate different treatment methods compared to polymeric coatings. Environmental Conditions: Consider the operating environment where the coated PEEK film will be used. High temperatures or exposure to chemicals may dictate the choice of both coating and surface treatment. Potential buyers seeking PEEK FILM Coating services should consult with experienced PEEK FILM manufacturers or suppliers to determine the most suitable surface treatment options for their specific applications. Engaging with suppliers who offer a range of surface treatment technologies can ensure that customers receive tailored solutions that meet their performance requirements. In conclusion, the adhesion of coatings on PEEK films is significantly influenced by various surface treatments. By understanding how mechanical, chemical, and thermal treatments affect adhesion properties, buyers can make informed decisions when selecting PEEK FILM Coating services. The right surface treatment not only enhances the performance and durability of coatings but also ensures that PEEK films can meet the demanding requirements of diverse applications across industries. Engaging with reputable PEEK FILM suppliers who understand these complexities will provide customers with high-quality products that deliver exceptional performance in their respective fields. As industries continue to evolve and demand more from materials, the importance of effective surface treatments will only grow, making it essential for buyers to prioritize this aspect when considering PEEK FILM Coating services. This completes the article! If you need any adjustments or additional information, feel free to ask!Introduction

1. Understanding PEEK Films

1.1 Properties of PEEK

1.2 Importance of Coatings on PEEK Films

2. The Role of Surface Treatments

2.1 Definition and Purpose

2.2 Common Surface Treatments for PEEK Films

3. How Surface Treatments Affect Adhesion

3.1 Mechanisms of Adhesion

3.2 Impact of Mechanical Treatments

3.3 Effects of Chemical Treatments

3.4 Influence of Thermal Treatments

4. Case Studies

4.1 Successful Applications

4.2 Comparative Analysis

5. Selecting the Right Surface Treatment

5.1 Factors to Consider

5.2 Recommendations for Buyers

Conclusion

Copyright © 2025 Guangzhou Furui New Material Technology Co., Ltd.| All Rights Reserved