BETTER TOUCH BETTER BUSINESS

Contact Sales at FURUI.

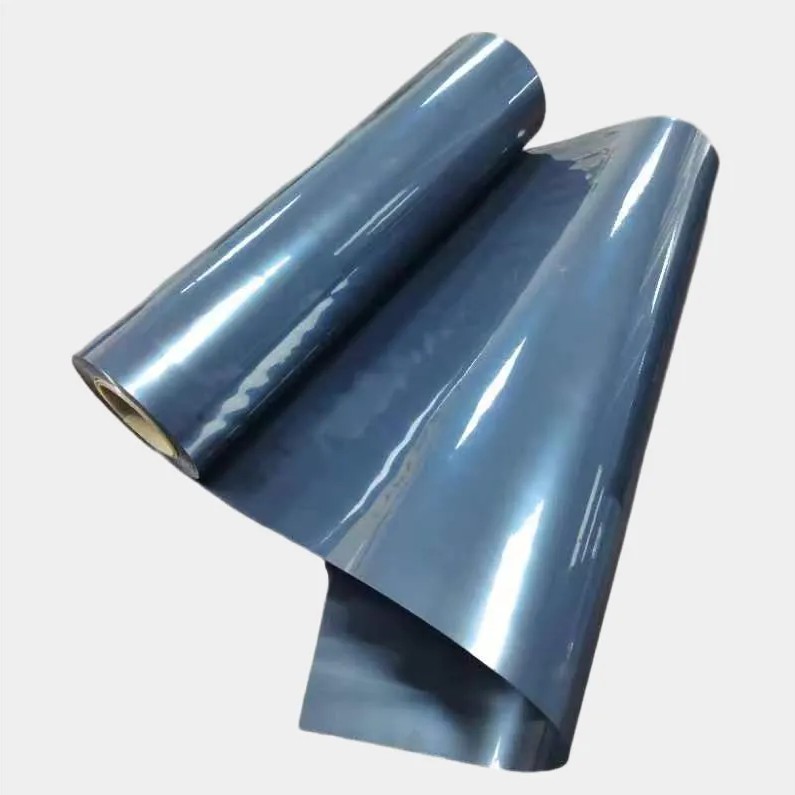

In today's world, sustainability has become a crucial factor in the selection of packaging materials. As consumers and businesses alike become more environmentally conscious, the demand for eco-friendly alternatives to traditional plastics has grown significantly. One such alternative is PEEK (Polyether Ether Ketone) film, a high-performance thermoplastic with unique properties that set it apart from conventional plastic films. This article aims to explore the differences between PEEK FILM and traditional plastic films in terms of sustainability, helping potential buyers make informed decisions when choosing packaging materials. PEEK film is a thin, flexible material made from PEEK, a high-performance thermoplastic known for its exceptional mechanical properties, chemical resistance, and thermal stability. The chemical structure of PEEK consists of an aromatic backbone with ether and ketone functional groups, which contribute to its unique characteristics. The manufacturing process of PEEK film involves several steps, including polymerization, extrusion, and stretching. This process differs from traditional plastic film production methods, which often rely on petroleum-based raw materials and energy-intensive processes. PEEK film manufacturers, such as Victrex and Solvay, have developed innovative techniques to optimize the production of this material while minimizing environmental impact. Traditional plastic films, such as polyethylene (PE) and polypropylene (PP), have a significant environmental impact throughout their lifecycle. From the extraction of raw materials to the disposal or recycling of the final product, these plastics leave a considerable carbon footprint. The production of traditional plastic films often involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change. One of the most pressing issues with traditional plastic films is their slow degradation rate in landfills and oceans. Many conventional plastics can take hundreds of years to break down, leading to the accumulation of plastic waste in the environment. This plastic pollution has devastating effects on marine life, ecosystems, and human health, as microplastics enter the food chain and water supply. Recycling traditional plastic films poses several challenges. The process can be costly and energy-intensive, and the quality of the recycled material may be inferior to virgin plastic. Additionally, the presence of contaminants and the difficulty in separating different types of plastics can further complicate the recycling process. As a result, many plastic films end up in landfills or incineration facilities, contributing to environmental pollution. In contrast to traditional plastic films, PEEK film offers more sustainable end-of-life options. While PEEK is not inherently biodegradable, it can be recycled and reused in various applications, reducing waste and conserving resources. PEEK film suppliers, such as Victrex and Solvay, have developed recycling programs to ensure that PEEK waste is properly managed and reintegrated into the production cycle. PEEK film's recyclability is a significant advantage over traditional plastic films. The material can be melted and reused multiple times without losing its properties, making it an ideal choice for closed-loop recycling systems. PEEK film manufacturers have invested in research and development to improve recycling processes and increase the availability of recycled PEEK material. The production of PEEK film has a lower environmental impact compared to traditional plastic films. PEEK film manufacturers use energy-efficient processes and renewable energy sources to reduce greenhouse gas emissions. Additionally, the material's durability and longevity contribute to a smaller carbon footprint over its lifetime, as less material is required to meet packaging needs. PEEK film's exceptional mechanical properties, including high tensile strength and impact resistance, make it a durable and long-lasting material. This durability translates to a longer lifespan for PEEK film-based packaging, reducing the need for frequent replacements and minimizing waste. PEEK film suppliers emphasize the material's performance advantages to highlight its sustainability benefits. The production of PEEK film is more energy-efficient compared to traditional plastic films. PEEK film manufacturers have invested in advanced technologies and processes to optimize energy consumption, such as using waste heat recovery systems and implementing lean manufacturing principles. This focus on energy efficiency contributes to the overall sustainability of PEEK film as a packaging material. PEEK film finds applications in various industries, including aerospace, medical, electronics, and automotive. Its unique properties, such as high temperature resistance, chemical inertness, and excellent dielectric properties, make it a preferred choice for demanding applications. As sustainability becomes a priority across these industries, the demand for PEEK film as a sustainable packaging material is expected to grow. Consumers are increasingly aware of the environmental impact of packaging materials and are actively seeking out sustainable alternatives. Businesses that incorporate PEEK film into their packaging can benefit from this growing consumer demand, as it demonstrates their commitment to sustainability and environmental responsibility. PEEK film suppliers can leverage this trend by highlighting the material's sustainability features and promoting its use in eco-friendly packaging solutions. While the initial cost of PEEK film may be higher compared to traditional plastic films, the long-term savings and benefits can outweigh the upfront investment. PEEK film's durability and recyclability can lead to reduced waste and disposal costs, while its energy-efficient production can contribute to lower operating expenses. Additionally, businesses that adopt PEEK film can benefit from positive brand perception and increased customer loyalty, which can translate into financial gains. The choice of packaging material can have significant economic implications for businesses. By selecting sustainable options like PEEK film, companies can demonstrate their commitment to environmental stewardship and align with the growing trend of corporate social responsibility. This alignment can lead to improved brand reputation, increased customer loyalty, and potential cost savings through reduced waste and disposal fees. PEEK film suppliers can assist businesses in understanding the economic benefits of adopting sustainable packaging solutions. In conclusion, PEEK film offers a sustainable alternative to traditional plastic films, with its unique properties, recyclability, and reduced environmental impact. As consumers and businesses become more conscious of the need for eco-friendly packaging solutions, PEEK film suppliers are well-positioned to meet this growing demand. By highlighting the advantages of PEEK film over conventional plastics, PEEK film manufacturers can help potential buyers make informed decisions that prioritize sustainability without compromising performance.Introduction

Understanding PEEK Film

Definition and Composition

Production Process

Environmental Impact of Traditional Plastic Films

Lifecycle Analysis

Degradation and Pollution

Recycling Challenges

Sustainability Features of PEEK Film

Biodegradability and End-of-Life Options

Recyclability

Reduced Environmental Footprint

Performance Characteristics Relevant to Sustainability

Durability and Longevity

Energy Efficiency in Production

Applications and Market Trends

Industries Utilizing PEEK Film

Consumer Demand for Sustainable Packaging

Cost Considerations

Initial Investment vs Long-term Savings

Economic Implications for Businesses

Conclusion

Copyright © 2025 Guangzhou Furui New Material Technology Co., Ltd.| All Rights Reserved