BETTER TOUCH BETTER BUSINESS

Contact Sales at FURUI.

High-temperature polymers play a crucial role in various industries due to their exceptional thermal stability and mechanical properties. Among these, PEEK (Polyetheretherketone) film stands out for its unique characteristics. This article aims to provide a comprehensive comparison of PEEK film with other high-temperature polymers, helping users make informed decisions when considering PEEK film for their applications. Whether you're searching for a reliable PEEK film supplier or exploring wholesale PEEK film options, understanding how PEEK film measures up against its counterparts will be valuable. High-temperature polymers are designed to maintain their performance and structural integrity under extreme temperatures. These materials are essential in applications where conventional polymers would fail due to thermal degradation. Commonly used high-temperature polymers include PEEK, PTFE (Polytetrafluoroethylene), PI (Polyimide), and PPS (Polyphenylene Sulfide). Each of these polymers has specific properties that make them suitable for different applications. For instance, some are favored for their excellent chemical resistance, while others are chosen for their superior mechanical strength or flexibility. PEEK film, or Polyetheretherketone film, is a high-performance polymer known for its remarkable thermal stability and mechanical strength. It is characterized by: High Thermal Stability: PEEK film can withstand continuous temperatures up to 260°C (500°F) without significant degradation. Excellent Mechanical Strength: It offers high tensile strength and resistance to wear and tear. Chemical Resistance: PEEK film is highly resistant to a wide range of chemicals, including acids, bases, and solvents. Electrical Insulation: It provides excellent electrical insulation properties, making it suitable for electronic applications. These attributes make PEEK film a versatile material, often used in demanding environments such as aerospace, electronics, and medical devices. To effectively compare PEEK film with other high-temperature polymers, we need to consider several criteria: Thermal Stability and Maximum Operating Temperatures: This criterion assesses how well the material performs under high temperatures and its ability to retain its properties over time. Mechanical Properties: Includes tensile strength, impact resistance, and overall durability. Chemical Resistance and Compatibility: Evaluates how the material withstands exposure to various chemicals and its suitability for specific environments. Electrical Insulation Properties: Important for applications requiring electrical insulation. Cost and Availability: Considers the material's cost and how readily available it is from suppliers. Thermal Stability and Maximum Operating Temperatures: PEEK Film: PEEK film maintains its properties at temperatures up to 260°C (500°F), making it suitable for high-temperature applications. PTFE: PTFE, commonly known as Teflon, can operate at temperatures up to 260°C (500°F) as well but has a higher coefficient of thermal expansion compared to PEEK. Chemical Resistance and Applications: PEEK Film: PEEK film is highly resistant to a broad spectrum of chemicals, including acids, bases, and solvents. Its robust chemical resistance makes it ideal for use in harsh chemical environments. PTFE: PTFE is known for its excellent chemical resistance, particularly against acids and bases. However, its lower mechanical strength compared to PEEK limits its use in structural applications. Mechanical Strength Comparison: PEEK Film: Offers superior mechanical strength and durability, making it suitable for demanding mechanical applications. PTFE: PTFE has lower mechanical strength and is more suited to applications where its non-stick and chemical-resistant properties are prioritized over mechanical strength. Temperature Performance and Flexibility: PEEK Film: PEEK provides high temperature performance with excellent dimensional stability under heat. It is less flexible compared to polyimide. Polyimide: Polyimide films, such as Kapton, also perform well at high temperatures, typically up to 400°C (752°F). Polyimide films are more flexible than PEEK, which can be beneficial for applications requiring conformability. Mechanical and Electrical Properties: PEEK Film: PEEK film excels in mechanical strength and is a good electrical insulator. Polyimide: Polyimide offers good mechanical properties and superior electrical insulation, making it a good alternative for electrical applications. Typical Applications and Cost Differences: PEEK Film: Often used in aerospace, automotive, and medical fields due to its high strength and resistance. Polyimide: Commonly used in electronics and flexible circuit boards. Generally, polyimide is less expensive than PEEK. Comparison of Thermal and Chemical Resistance: PEEK Film: Provides superior thermal and chemical resistance compared to PPS. PEEK can handle more severe conditions without degradation. PPS: PPS is also chemically resistant and performs well under high temperatures, but it generally has lower mechanical strength than PEEK. Mechanical Strength and Performance in Harsh Environments: PEEK Film: Due to its high mechanical strength, PEEK is preferred for structural components in harsh environments. PPS: While PPS is durable, its mechanical strength does not match that of PEEK, limiting its use in extreme conditions. Cost and Practical Applications: PEEK Film: Typically more expensive due to its superior properties but preferred for high-performance applications. PPS: More cost-effective and suitable for less demanding applications. Choosing PEEK film over other high-temperature polymers can offer several advantages, including: Superior Performance: PEEK film provides unmatched thermal stability, mechanical strength, and chemical resistance. Versatility: It is suitable for a wide range of applications, from aerospace to medical devices. Durability: Its longevity and reliability in extreme conditions make it a preferred choice for demanding environments. When considering purchasing PEEK film, keep the following factors in mind: Application-Specific Requirements: Ensure that PEEK film meets the specific needs of your application, including temperature, chemical exposure, and mechanical demands. Cost Considerations: Evaluate the cost of PEEK film relative to its benefits and your budget. Supplier Reliability: Choose a reputable PEEK film supplier who can provide high-quality products and support. Availability and Customization: Check for availability and options for customization based on your requirements. In conclusion, PEEK film stands out among high-temperature polymers for its exceptional performance, durability, and versatility. By comparing it with other polymers like PTFE, Polyimide, and PPS, users can better understand its advantages and make informed decisions. Whether you are looking for wholesale PEEK film or seeking a specific PEEK film supplier, understanding these comparisons will help you choose the best material for your needs.Introduction

Overview of High-Temperature Polymers

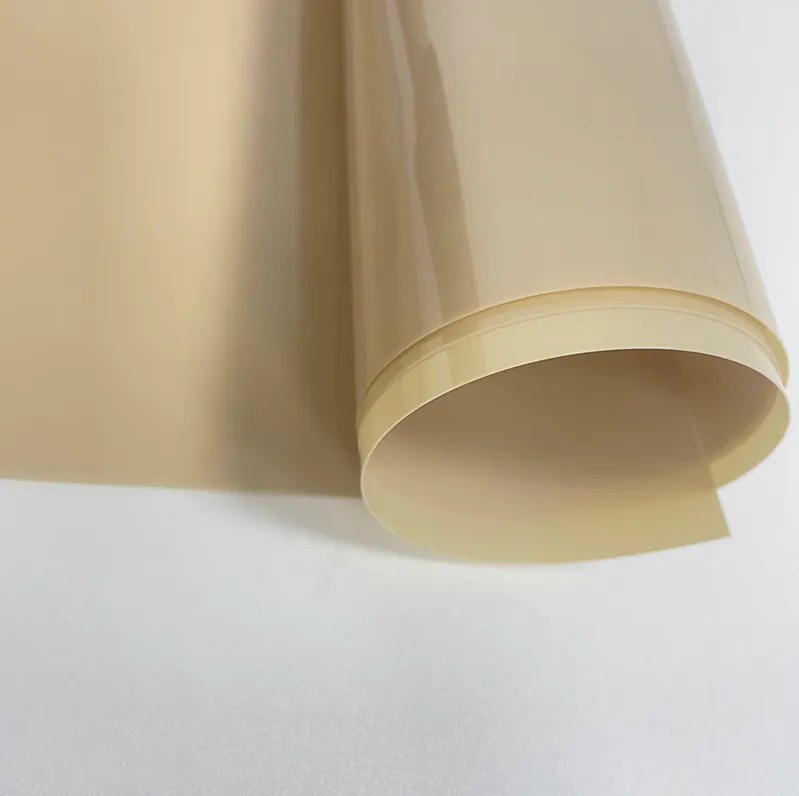

What is PEEK Film?

Comparison Criteria for High-Temperature Polymers

Comparing PEEK Film to Other High-Temperature Polymers

PEEK vs. PTFE (Polytetrafluoroethylene)

PEEK vs. PI (Polyimide)

PEEK vs. PPS (Polyphenylene Sulfide)

Advantages of Choosing PEEK Film

Factors to Consider When Purchasing PEEK Film

Conclusion

Copyright © 2025 Guangzhou Furui New Material Technology Co., Ltd.| All Rights Reserved