BETTER TOUCH BETTER BUSINESS

Contact Sales at FURUI.

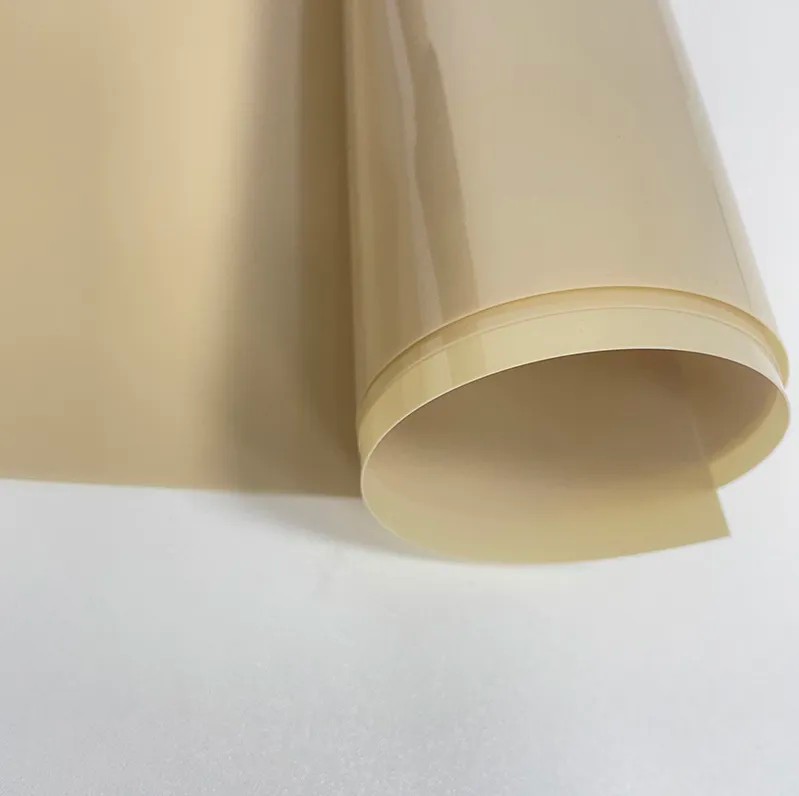

In the ever-evolving field of medical technology, PEEK FILM has emerged as a game-changing material for medical implants. This high-performance polymer, known for its exceptional properties, has revolutionized the way we approach implant design and manufacturing. As potential buyers in the medical industry, understanding the key applications of PEEK FILM in medical implants is crucial for making informed decisions. This article aims to explore the various uses of PEEK FILM in medical implants, highlighting its unique properties and advantages over traditional materials. Whether you're a medical device manufacturer, a researcher, or a healthcare professional, this comprehensive guide will provide valuable insights into why PEEK FILM has become an indispensable material in the medical implant industry. PEEK, or Polyether Ether Ketone, is a high-performance thermoplastic polymer that forms the basis of PEEK FILM. This remarkable material boasts a unique combination of properties that make it ideal for medical implant applications: Biocompatibility: PEEK FILM is inert and does not cause adverse reactions in the human body. Chemical resistance: It withstands degradation from bodily fluids and sterilization processes. Mechanical strength: PEEK FILM offers excellent strength-to-weight ratio and fatigue resistance. Thermal stability: It maintains its properties at high temperatures, crucial for sterilization processes. These properties have made PEEK FILM a preferred choice for many PEEK FILM manufacturers and has led to an increase in wholesale PEEK FILM distribution for medical applications. The production of high-quality PEEK FILM involves sophisticated manufacturing processes: Extrusion: The PEEK polymer is melted and forced through a die to create sheets or films. Biaxial orientation: The film is stretched in both machine and transverse directions to enhance its mechanical properties. Heat treatment: This process ensures dimensional stability and optimal crystallinity. Reputable PEEK FILM manufacturers adhere to strict quality control measures, including cleanroom environments and rigorous testing protocols, to ensure the final product meets the exacting standards required for medical implants. PEEK FILM is extensively used in spinal implants, including cages and rods. Its radiolucency allows for clear imaging without interference, making post-operative assessments easier. Additionally, its mechanical properties closely mimic those of human bone, reducing stress shielding and promoting better patient outcomes. In orthopedic applications, PEEK FILM is utilized in joint replacements such as hip and knee implants. Its wear resistance and durability make it an excellent alternative to traditional materials like metals. Furthermore, PEEK FILM reduces the risk of metal ion release, which can lead to complications such as metallosis. PEEK FILM is gaining popularity in dental prosthetics and abutments due to its lightweight nature and biocompatibility. It can be easily customized to fit individual patient needs, providing a comfortable and durable solution for dental restorations. In the cardiovascular field, PEEK FILM is used in stents and heart valve components. Its flexibility and chemical resistance ensure long-term stability and performance. The material's ability to withstand the harsh environment of the human body makes it a reliable choice for life-saving devices. PEEK FILM is also employed in neurological implants, such as neural probes and brain electrodes. Its biocompatibility and electrical insulation properties minimize inflammatory responses and ensure effective signal transmission, making it ideal for sensitive neurological applications. Compared to metals, PEEK FILM offers several advantages: Weight: PEEK FILM is significantly lighter, reducing the overall weight of implants. Corrosion resistance: Unlike metals, PEEK FILM does not corrode, ensuring longevity. Imaging compatibility: PEEK FILM is radiolucent, allowing for clear imaging without artifacts. When compared to other polymers, PEEK FILM stands out due to: Mechanical strength: PEEK FILM offers superior strength and fatigue resistance. Thermal stability: It maintains its properties at high temperatures, essential for sterilization. Chemical resistance: PEEK FILM is resistant to a wide range of chemicals, ensuring durability. When purchasing PEEK FILM, it is crucial to ensure that the product meets high-quality standards. Look for PEEK FILM manufacturers that have ISO and FDA certifications, which guarantee biocompatibility and safety. These certifications are essential for medical applications and ensure that the PEEK FILM you purchase is suitable for use in implants. Choosing the right supplier is vital. Consider the following criteria: Reputation: Opt for a reputable PEEK FILM manufacturer known for quality and reliability. Technical support: Ensure the supplier offers technical support and customization options to meet your specific needs. Wholesale options: If you require large quantities, look for suppliers that offer wholesale PEEK FILM to get the best value for your investment. While cost is an important factor, it should not compromise quality. Factors influencing the cost of PEEK FILM include the manufacturing process, quality control measures, and certifications. Balancing quality and budget considerations is key to making a wise investment. PEEK FILM has become an indispensable material in the medical implant industry due to its unique properties and versatile applications. From spinal and orthopedic implants to dental, cardiovascular, and neurological devices, PEEK FILM offers unparalleled benefits over traditional materials. For those looking to purchase PEEK FILM, understanding its advantages and applications is crucial for making informed decisions. By choosing a reputable PEEK FILM manufacturer and considering factors such as quality, certification, and cost, you can ensure that you are investing in a material that will enhance the performance and longevity of your medical implants. Whether you are looking for wholesale PEEK FILM or specialized solutions, PEEK FILM stands out as a superior choice for medical applications.Introduction

1. Overview of PEEK Film

1.1. Composition and Properties

1.2. Manufacturing Process

2. Key Applications of PEEK Film in Medical Implants

2.1. Spinal Implants

2.2. Orthopedic Implants

2.3. Dental Implants

2.4. Cardiovascular Implants

2.5. Neurological Implants

3. Advantages of PEEK Film Over Other Materials

3.1. Comparison with Metals

3.2. Comparison with Other Polymers

4. Considerations for Purchasing PEEK Film

4.1. Quality and Certification

4.2. Supplier Selection

4.3. Cost and Budget

Conclusion

Copyright © 2025 Guangzhou Furui New Material Technology Co., Ltd.| All Rights Reserved