BETTER TOUCH BETTER BUSINESS

Contact Sales at FURUI.

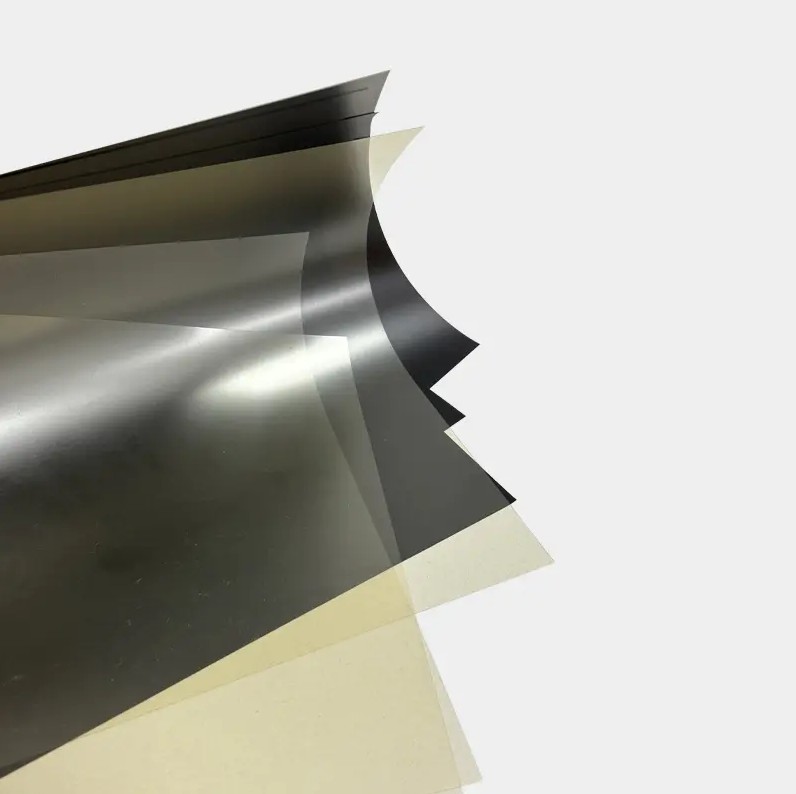

In the rapidly evolving world of flexible electronics, the choice of materials plays a crucial role in determining the performance and reliability of devices. Among these materials, PEI FILM, or polyetherimide film, has emerged as a popular choice due to its unique combination of properties. However, to fully harness the potential of PEI films in flexible electronics, understanding and optimizing their adhesion properties is paramount.

Surface modification of PEI films has become a key area of focus for both researchers and PEI FILM manufacturers. This process can significantly enhance the adhesion properties of the film, making it more suitable for a wide range of applications in flexible electronics. But how exactly does surface modification affect these properties, and what should potential buyers know when selecting a PEI film for their specific needs?

This article aims to delve into the intricacies of surface modification techniques for PEI films and their impact on adhesion properties in flexible electronics. Whether you're a product designer, an engineer, or a procurement specialist, understanding these concepts will help you make informed decisions when choosing the right polyetherimide FILM for your flexible electronic applications.

Before we explore surface modification techniques, it's essential to understand what makes PEI films unique. Polyetherimide (PEI) is a high-performance thermoplastic known for its excellent thermal, mechanical, and electrical properties. PEI FILM, the thin sheet form of this material, inherits these properties, making it an attractive option for flexible electronics.

PEI films consist of repeating units of aromatic imides and ethers in their polymer backbone. This structure contributes to their high glass transition temperature, excellent dimensional stability, and good chemical resistance. These properties make PEI films particularly suitable for applications that require high-temperature resistance and dimensional stability.

PEI films offer several advantages in flexible electronics:

High heat resistance

Excellent electrical insulation properties

Good mechanical strength and flexibility

Low moisture absorption

Flame retardancy

These properties make PEI films ideal for applications such as flexible printed circuit boards, flexible displays, and wearable devices.

Despite their numerous advantages, unmodified PEI films have some limitations, particularly in terms of adhesion properties. The surface of unmodified PEI films is relatively inert, which can lead to poor adhesion with other materials in multilayer structures. This is where surface modification becomes crucial.

To overcome the adhesion limitations of unmodified PEI films, various surface modification techniques have been developed. These techniques aim to alter the surface properties of the film without affecting its bulk characteristics. Let's explore some of the most common methods employed by PEI FILM manufacturers:

Plasma treatment involves exposing the PEI film surface to ionized gas. This process can introduce functional groups, increase surface energy, and improve wettability. Plasma treatment is particularly effective in enhancing the adhesion of PEI films to metals and other polymers.

Chemical etching uses specific solvents or reactive solutions to modify the PEI film surface. This technique can create a rougher surface topography, increasing the surface area available for bonding. However, care must be taken to control the etching process to avoid compromising the film's integrity.

UV/Ozone treatment exposes the PEI film to ultraviolet light in the presence of ozone. This process can oxidize the surface, introducing polar groups that enhance adhesion. It's a relatively simple and environmentally friendly method that's gaining popularity among polyetherimide FILM producers.

This advanced technique involves attaching specific molecules or functional groups to the PEI film surface. By carefully selecting the grafted molecules, manufacturers can tailor the surface properties to meet specific adhesion requirements.

The surface modification techniques mentioned above can significantly enhance the adhesion properties of PEI films in several ways:

Surface modification typically increases the surface energy of PEI films, improving their wettability. This enhanced wettability allows for better contact and interaction with adhesives or other materials, leading to stronger bonds.

Many surface modification techniques introduce functional groups on the PEI film surface. These groups can form chemical bonds with adhesives or other materials, significantly improving adhesion strength.

Some modification techniques, particularly chemical etching, can increase the surface roughness of PEI films. This increased roughness provides more surface area for mechanical interlocking, enhancing adhesion through physical means.

Certain surface modifications can alter the electrostatic properties of the PEI film surface. This can lead to improved adhesion through electrostatic interactions, particularly useful in applications involving charged particles or materials.

The improved adhesion properties of surface-modified PEI films have opened up new possibilities in various flexible electronics applications:

In flexible OLED displays, PEI films with enhanced adhesion properties can serve as reliable substrates, ensuring better bonding with electrode materials and organic layers.

Surface-modified PEI films can provide excellent adhesion for conductive inks and other functional materials used in wearable sensors and electronic textiles.

The improved adhesion of modified PEI films allows for better bonding with copper foils and other conductive materials in flexible PCBs, enhancing reliability and durability.

In flexible photovoltaic devices, surface-modified PEI films can serve as substrates with improved adhesion to active layers, potentially increasing the efficiency and lifespan of flexible solar cells.

For buyers looking to purchase PEI FILM for flexible electronics applications, several factors should be considered:

Specific application requirements

Compatibility with other materials in the device

Environmental conditions during use

Manufacturing processes involved

Peel strength

Shear strength

Surface energy

Chemical resistance

Thermal stability

While surface-modified PEI films may be more expensive than unmodified versions, the improved performance and reliability often justify the additional cost. Buyers should consider the long-term benefits and potential cost savings from improved product performance and reduced failure rates.

Several companies have successfully implemented surface-modified PEI films in their products. For instance, a major smartphone manufacturer used plasma-treated PEI films in their flexible display technology, resulting in improved durability and longer product lifespan.

When compared to other flexible substrate materials like polyimide, surface-modified PEI films often show superior adhesion properties and thermal stability, making them a preferred choice for high-performance flexible electronics.

Research is ongoing into new surface modification techniques, such as nanoparticle coating and biomimetic surface treatments. These emerging methods promise even greater control over surface properties and adhesion characteristics.

As surface modification techniques continue to advance, new applications for PEI films in flexible electronics are emerging. These include stretchable electronics, conformable displays, and advanced medical devices.

Surface modification of PEI films plays a crucial role in enhancing their adhesion properties for flexible electronics applications. By altering the surface characteristics without affecting the bulk properties, these techniques enable PEI films to meet the demanding requirements of modern flexible electronic devices.

For buyers and engineers working with flexible electronics, understanding the impact of surface modification on PEI films is essential. When selecting a PEI FILM manufacturer or product, consider not only the base material properties but also the surface modification techniques employed and their effects on adhesion.

As the field of flexible electronics continues to evolve, surface-modified PEI films are likely to play an increasingly important role. By staying informed about the latest developments in this area, you can ensure that you're making the best material choices for your flexible electronic applications, balancing performance, reliability, and cost-effectiveness.

Copyright © 2025 Guangzhou Furui New Material Technology Co., Ltd.| All Rights Reserved